Subjects

Hydraulic pumps and motors are used in several applications. They are utilized in mobile construction machinery, industrial facilities, cars and utility vehicles, ships and aviation.

P&G Hydraulik is a service provider on hydraulic engineering tasks. We are specialized on hydraulic machines and can support you with different services.

Development

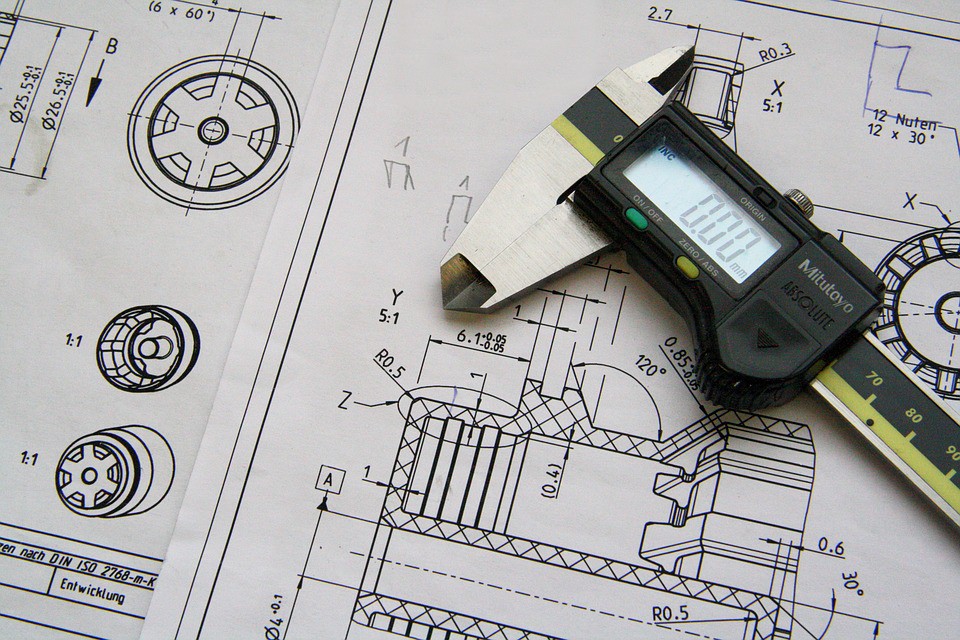

The development of hydraulic pumps and motors causes a high effort before series production can be reached. Design and manufacturing of all machine parts have to be done with high accuracy and carefulness.

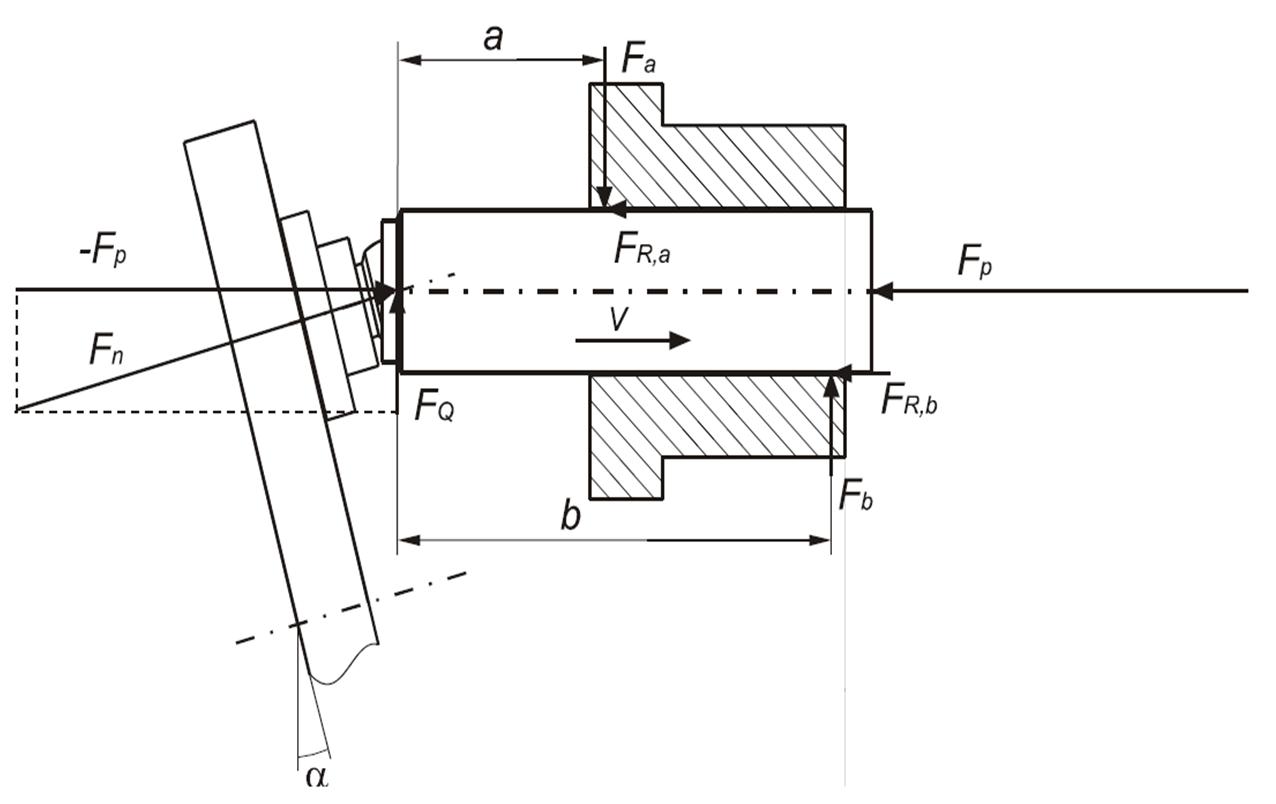

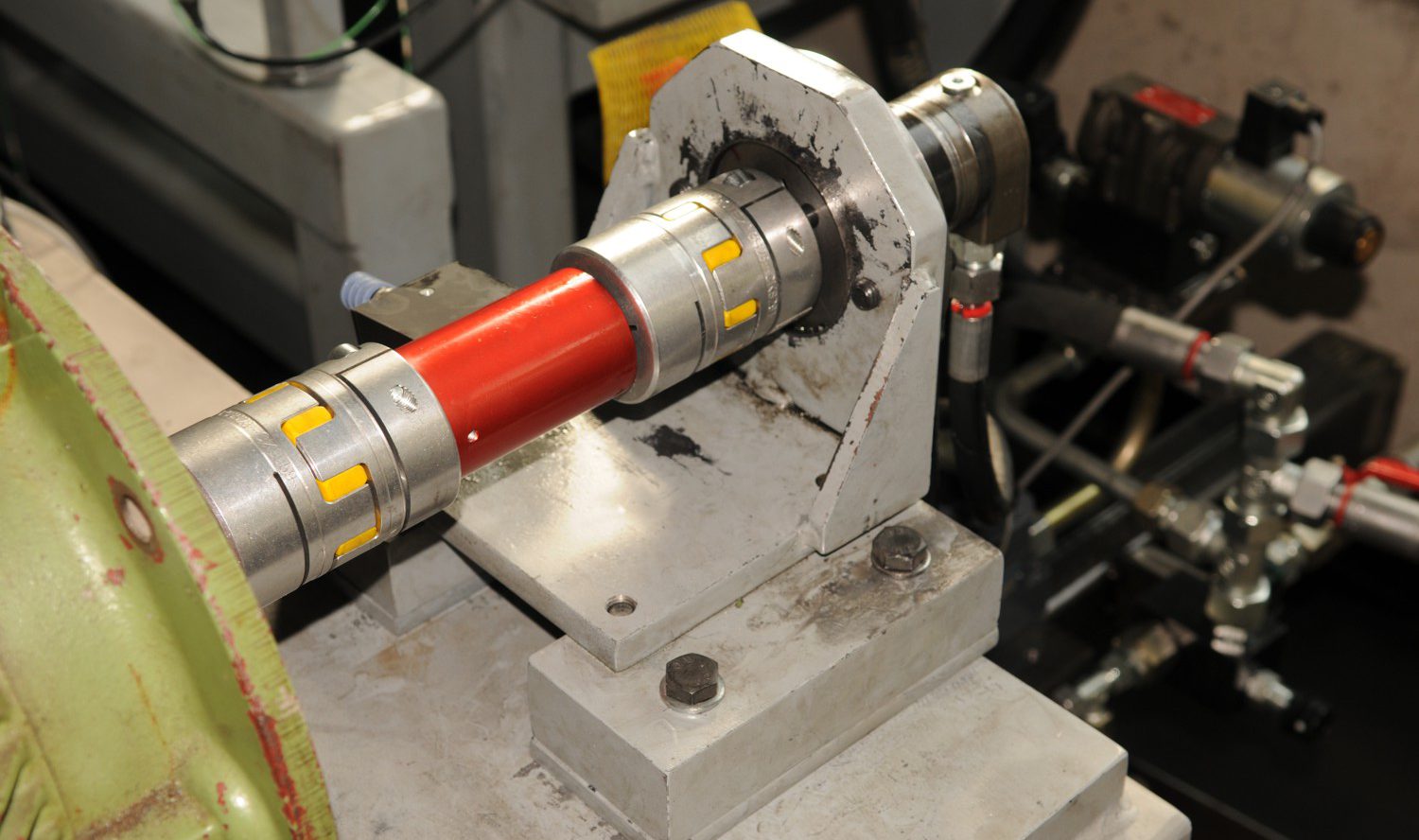

The difficulties in the design process of hydraulic machines result from the high pressure forces acting in the rotating group of the hydraulic machines. These high forces have to be carried by small and oil filled gaps (the tribological contacts or tribological interfaces).

The general requirements of a hydraulic application needs different types of pumps (piston pumps, gear pumps, screw pumps etc.), different pressures and speeds and the fluid might need different properties and viscosities. Therefore, a good amount of knowledge and experience is required to design a hydraulic pump or motor. Especially knowledge in the areas of tribology, material sciences, general machine construction and on production technology are required.

We support you with your new designs and improvements on existing hydraulic machines.

Simulation

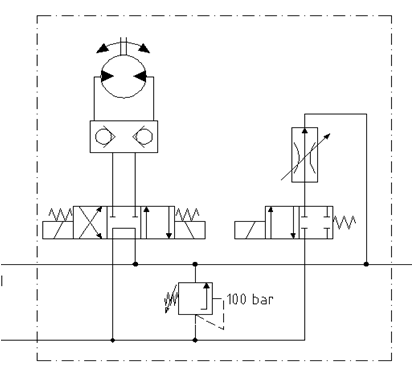

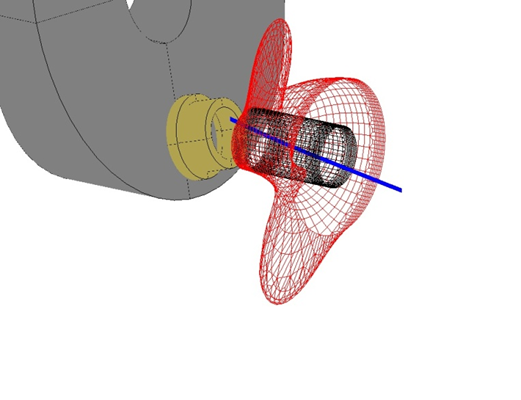

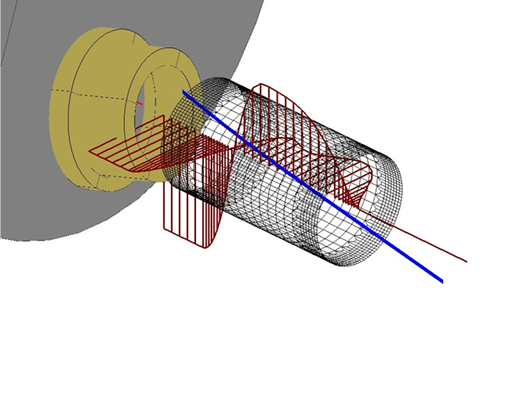

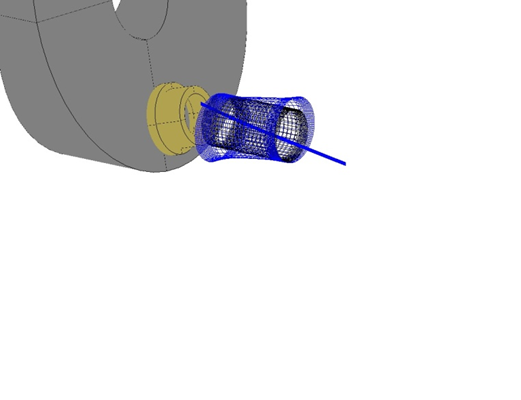

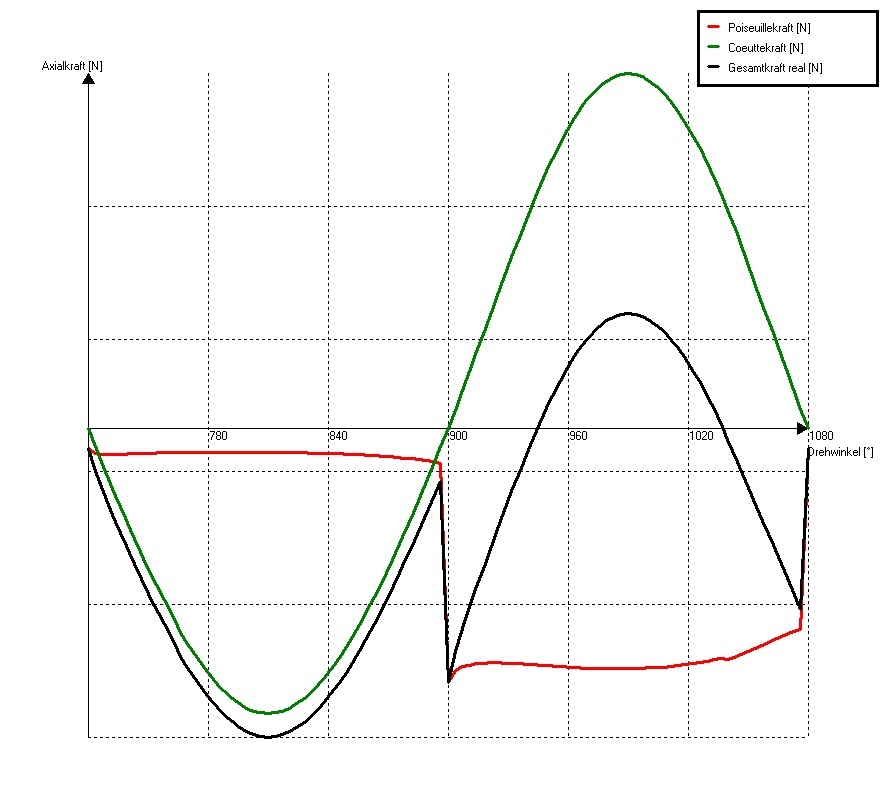

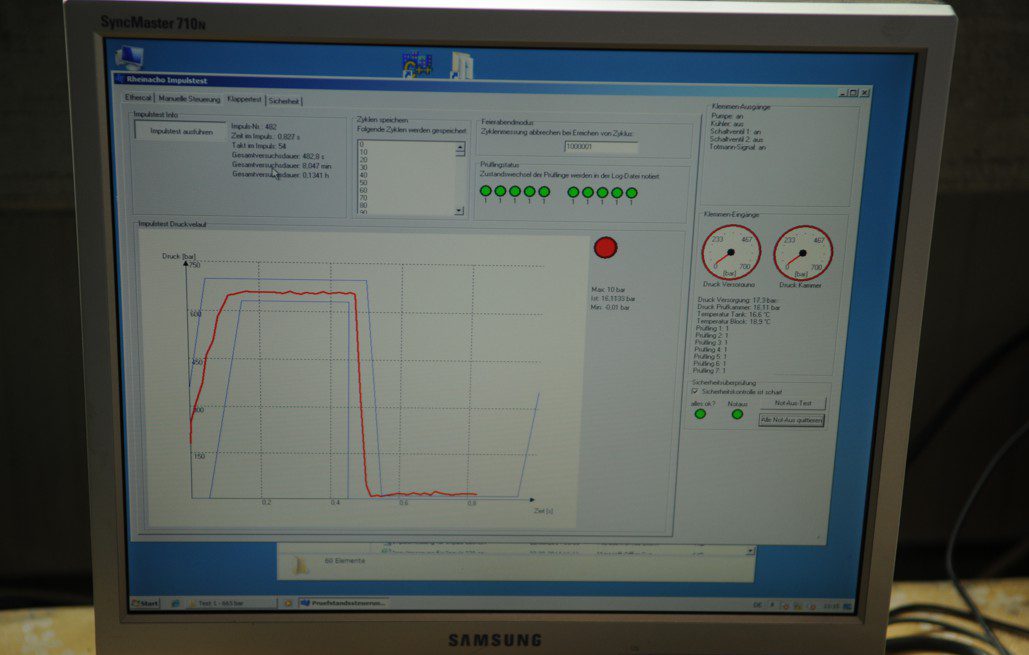

Our field of activities also includes the simulation of pressure and volume flow ripples of pumps as well as the simulation of tribological contacts.

Tribological contacts have a high importance in hydraulic machines because they should cause low friction and leakage and the operation should be without significant wear. We develop specialized simulation programs to simulate tribological contacts of axial piston machines.

To simulate the volume flow and pressure ripple of hydraulic pumps, system simulation programs are used. With these programs reasons for the pulsation can be found and afterwards the pulsation can be optimized.

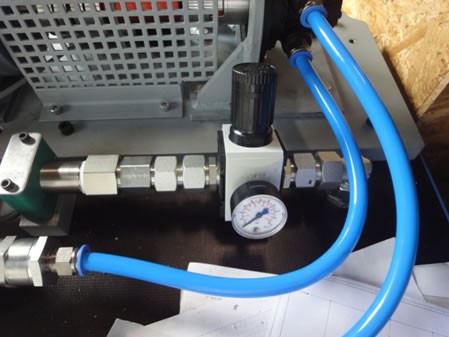

Prototypes

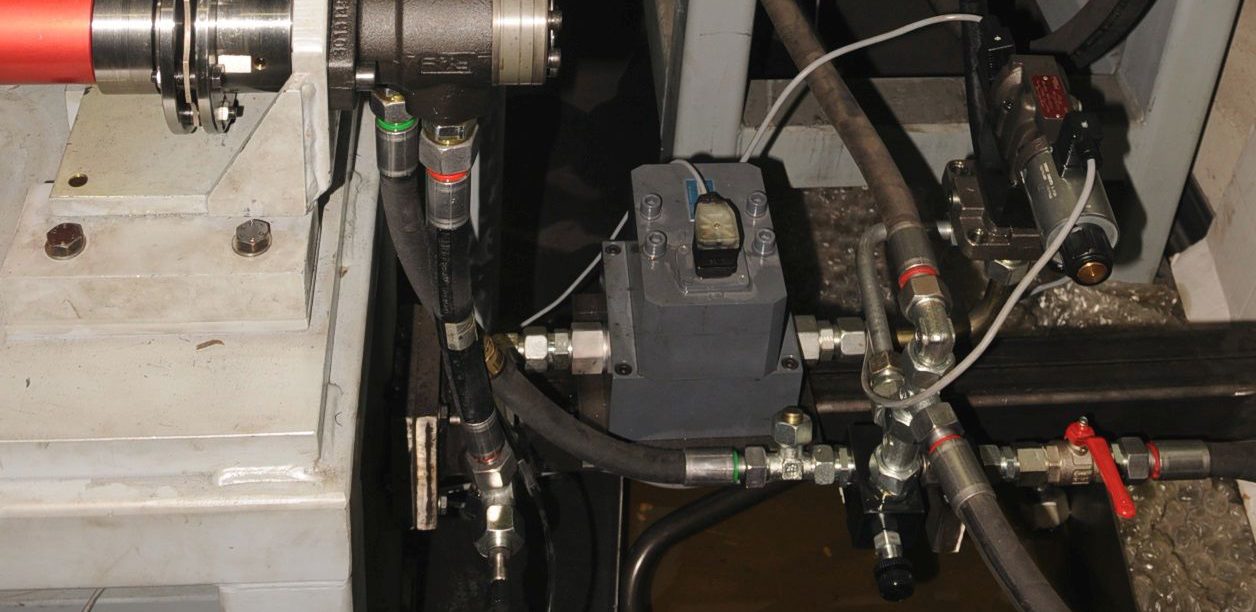

On individual problems with hydraulic machines we can support you with our knowledge and give innovative approaches for improvements. We support you with modifying existing components, new designs, build-up of prototypes and design and manufacturing of test-benches.

We are able to do design modifications and project planning also for small series production.

Consulting

Existing mobile and stationary hydraulic systems can be optimized to reduce the fuel consumption or the required electric power.

Possible measures for reductions are:

- Use of variable speed pump

- Avoiding power losses in valves by using variable displacement pumps

- Different strategies for pump displacement control (pressure control, flow control, load sensing…)

Our consulting service is independent from any manufacturer. We advise you to find functional and practical solutions for industrial applications.